Introduction

The objective of this guide is to help you find the most suitable integration dataflow based on your system, warehouse operations and various constraints with different integration methods. Understanding how printing integrates with each workflow is crucial for successful implementation.

Each workflow combines operational processes with appropriate printing mechanisms to create a seamless end-to-end integration. We'll explore how these elements work together in each scenario.

Core Workflows

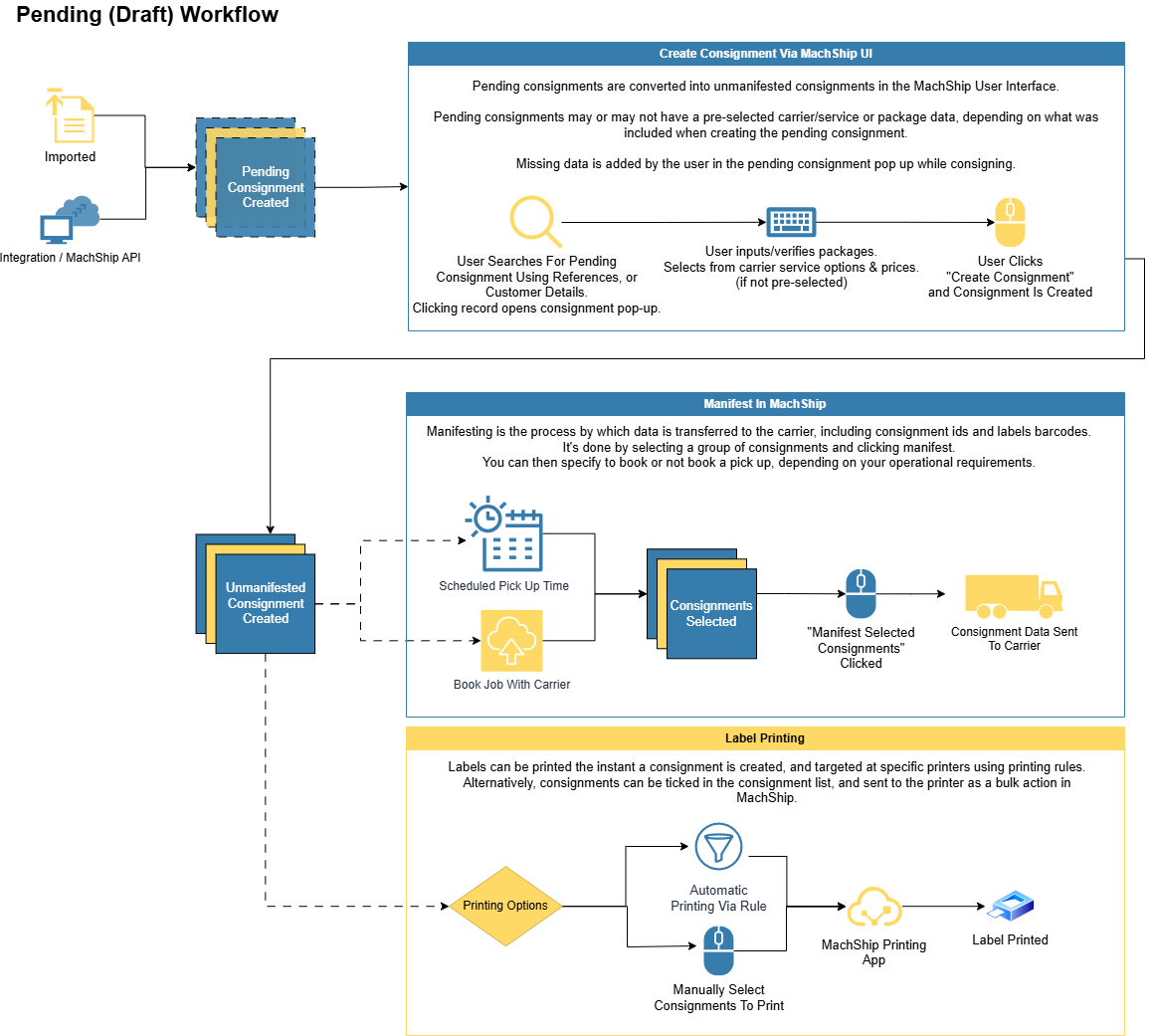

Pending Consignment Workflow

The pending consignment workflow is designed for scenarios where user intervention is needed during the shipping process. This workflow is particularly valuable when you need price comparison, manual package data entry, or handling of dangerous goods.

When to Use Pending Consignments

You should consider the pending consignment workflow when any of the following is true:

- You want users to see and select from available carrier prices in MachShip

- Package details aren't fully known at creation time

- Your system lacks complete package data (dimensions, weight, package type)

- Manual package data entry is part of your workflow

- You're handling dangerous goods without complete DG data

- You want users to validate details before creating a consignment

Implementation Process

In the pending workflow, your integration creates partially completed draft consignments in MachShip. Here's how it works:

-

Your integration pre-creates pending consignments with essential information:

- From and to addresses are prefilled

- Order or shipment number is added as a reference

- Any known package information can be included

-

The warehouse process then follows:

- Users pick and pack the order

- They access the pending consignment screen in MachShip

- They locate the consignment using the order/shipment number

- Package details are added or verified

- Carrier selection is made from available options

- Labels print

- At the end of the day, or when it suits, consignments are manifested in MachShip

Further Details On Pending Consignment Workflow

For further details on how to implement a pending consignment workflow, read our pending consignment workflow guide here.

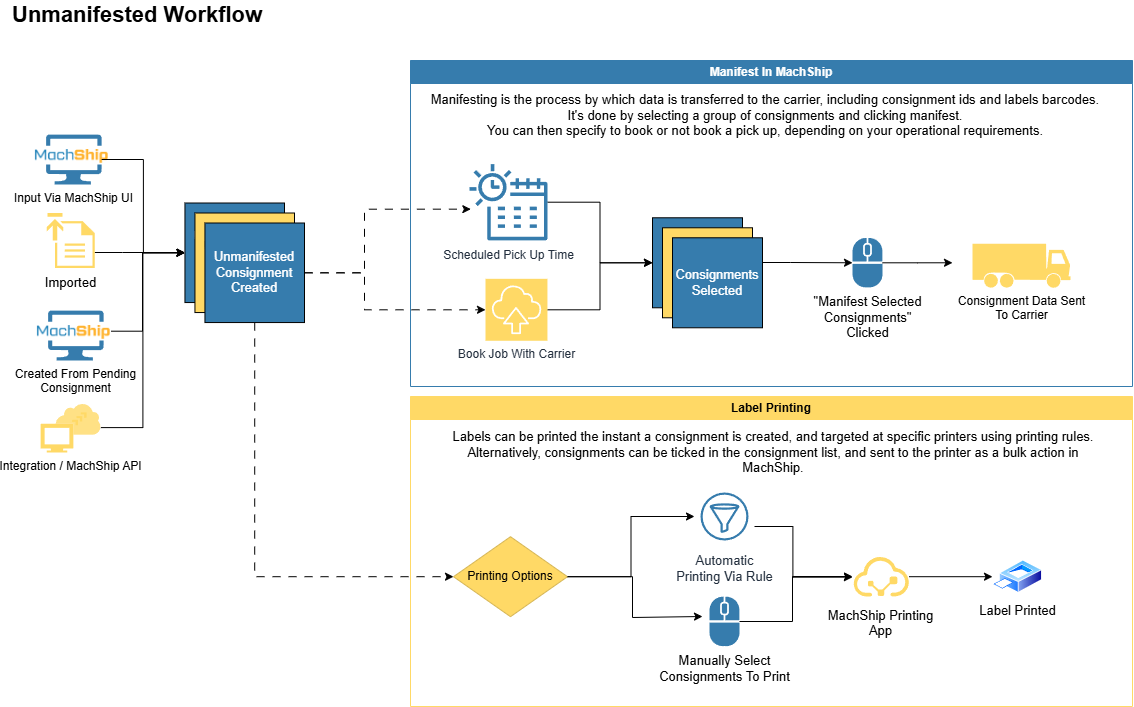

Unmanifested Consignment Workflow

The unmanifested workflow is designed for fully automated processing where all shipping details are known upfront.

In order to jump straight to creating an unmanifested consignment, you must have complete data in your system to do so. This includes:

- Valid from & to address

- Package data - including length, width, height and weight of all packages*

*Note, you can use standard packages, or products, and have that data stored in MachShip which removes the need to know the dimensions in your system.

If you do not have package data in your system, and do not have standardised packages, then you will need to use a pending consignment workflow where the data can be captured prior to creating the consignment.

This workflow comes in two variants:

Standard Unmanifested Workflow

This is the most common approach, utilising MachShip's consignment IDs, barcodes, and labels with immediate label printing.

When a trigger occurs in your system (like an order being ready to ship), you create a consignment with all details - addresses, references, and complete package information. MachShip immediately:

- Creates the consignment

- Allocates a carrier consignment ID

- Generates the required labels

When using this method, for carrier selection you can either:

- Route Fastest - MachShip will allocate the fastest carrier and service based on the packages

- Route To Cheapest - MachShip will allocate the cheapest carrier and service based on the packages

- Pre-Select A Carrier - and MachShip allocates the cheapest service for that carrier given the packages provided

- Pre-Select A Carrier AND Service

In summary, the workflow is:

- You create a consignment - this can be done using API, flat file or one of our other supported integration methods.

- Labels are print and are applied to the consignment packages

- Consignments are manifested in bulk to notify the carrier.

Unmanifested Workflow With Pre-Routing

This method is similar to the one above, but with the addition of a "return routes" API call - which will give you a list of all the carrier service options and their prices.

You can then use this response to display options to your user to choose from, or programatically select from those options - this selection would then be included as the pre-selected carrier and service on your create consignment request.

In summary, the workflow is:

- You send a return routes request with from, to address and packages

- We return a list of carrier and service options with etas and costs

- You follow up with a createConsignment call - including your desired pre-selected carrier and service

- Labels are printed and applied to the consignment

- Consignments are manifested to notify the carrier.

This consignment can only be implemented using the MachShip API.

Printing From Unmanifested Consignments

For printing in this workflow, you have several options:

Printer Token Printing (Most Common): MachShip has a field in our API known as a "printer token". This token can be passed at the time of making a API request, and also through our flat file methods.

The value can be anything meaningful to your operation - user IDs, desk locations, or warehouse zones.

When creating a consignment, you include the relevant printer token value, and MachShip routes the labels to the correct printer based on your configured rules in MachShip where you can target a printer token to a specific printer.

For simpler setups with a single printer, you can skip the printer token and use a default warehouse-wide rule instead.

API-Driven Printing: You can trigger label printing programmatically using the /apiv2/labels/sendLabelsToPrinter endpoint. This gives you control over when and where labels print while still utilizing MachShip's printer infrastructure.

UI-Based Printing: Users can leverage MachShip's interface to search, filter, and bulk print labels as needed. This is particularly useful for batch processing or when manual intervention is preferred.

Internal Label Management: If you need complete control over the printing process, you can retrieve label PDFs through the /apiv2/labels/getItemPdfFileInfo endpoint and manage printing entirely within your system.

Advanced Warehouse Workflows

The following workflows are less common, but have been included to help those users that have more advanced requirements.

1. Picking By Carrier

This workflow is for customers that want to use the "least cost" carrier, and need to know which carrier a consignment will be going with prior to picking, and before they know the final weights and dimensions of the items that will be put on the consignment.

To understand this workflow, you should know:

- A consignment cannot be created in MachShip without weights and dimensions of the packages/items - they are a requirement to create a consignment

- Service availability is affected by weights and dimensions of products

Based on this, the workflow you will implement is:

- Do a request to returnRoutes with the from, and to details, and a reasonable estimate of the final packages - this will return all the carrier service options, ETAs and prices

- Store the cheapest carrier, or the carrier that meets your criteria

- Do a create consignment request at a later time, and include the carrierId that you stored in step 1

Note, the final carrier that would have been cheapest could have been another carrier if the estimated final packages used when requesting prices is not reasonably accurate.

An example of this would be you did 5 cartons, but then later palletised - the cheapest pallet carrier may not be the cheapest carton carrier.

2. Picking By Product

This workflow applies for warehouses that pick multiple orders at one time, picking the same product for multiple orders at once, and you want MachShip to generate the labels at the time of picking each product.

The way the workflow needs to be implemented revolves around the following features of MachShip:

- Specific Labels Cannot Be Targeted For Printing - If you were to create a consignment in MachShip with all items allocated to it, there is no current method to tell MachShip to print to a specific label, or limited labels - it's all labels only.

- Consolidation - MachShip has a feature known as consolidation, where new consignments created for the same receiver can be automatically merged into existing consignments, and we send the newly added labels only to a printer

Based on this, the workflow you will implement is:

- As a picker reaches a given area for picking, a createConsignment request is made for each receiver, with the items on the consignment limited to the items about to be picked

- MachShip will create a consignment, or consolidate the consignment into an existing one for that same receiver, then send the new labels to the specified printer

This workflow is not required if you do not partially pick orders, AND you are not managing your own printing of the labels.

In that case, you can simply do a create consignment API call with all products at the start, then either: a) Get our book of labels, and split it, sending a label to the printer as it's needed b) Generate your own label, using your own reference, or ours, and sending it to the printer as it's needed

3. Print Then Pick

This workflow reverses the typical order - printing labels before picking begins. It's particularly effective for eCommerce operations or situations where orders typically ship in single boxes.

The process for this workflow is:

- Create unmanifested or pending consignments via the API, with all the details

- Use MachShip UI to sort, filter, select and bulk create and print groups of consignments

- Pick orders and apply labels

- Manifest in MachShip

4. Create For Connote & Barcodes, Then Edit With Final Consignment Dimensions

This workflow is for situations where you need to know the carrier and get a consignment id and barcodes prior to picking and packing, and you don't yet know the final item weights and dimensions.

This workflow is most common when: a) you are incorporating the MachShip generated connote and barcode into your label b) you need the barcodes prior to picking and packing c) you don't know the final item weights and dimensions prior to picking and packing

The process to implement for this workflow is:

- Create consignment with estimated dimensions, and equal to or greater than the number of items you will need

- Store the consignment ID and barcodes returned in the response

- Do an edit call on the unmanifested consignment with accurate details after picking/packing, and removing any unused barcodes

- Labels can be generated internally

Important considerations:

- Ensure you pass in an accurate list of the barcodes used

- The carrier that would have been cheapest could change based on final dimensions of the items

Related Documentation

For more detailed information about specific aspects of these workflows, please refer to our printer setup guides, API documentation, and manifest processing guide.